If you are a regular at the shooting range, you know that ammunition supply is a critical part of your routine.

You may have already invested in a small single-stage press to reload a few rounds of ammunition. However, as time goes by and you look at all that beautiful brass laying on the range, you realize that perhaps you are missing a beat in not reloading more.

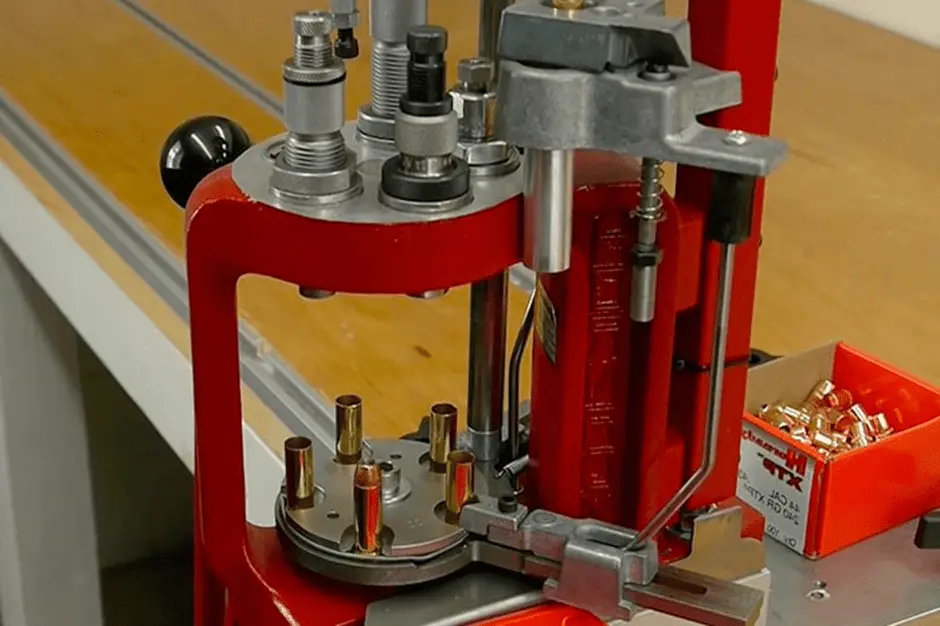

Progressive reloading presses are more efficient than either a turret press or a single-stage press. A progressive reloading press typically holds all of the reloading dies in your set and moves the shell casing around so that each pull of the press handle completes a finished cartridge.

You can’t beat a good progressive reloading press when you need to process and load a lot of empty cartridge cases in a short period of time.

Most modern progressive reloading presses have features that automate much of the reloading process to increase consistency and efficiency. The best progressive reloading presses may even feature automatic case loading and primer feed systems.

Progressive or Turret – What’s the Difference?

Turret or Progressive? What is the difference between these two popular styles of reloading presses?

Visually, they do seem similar, but the way these two presses work is much different. Understanding how these types of reloading presses work is critical to deciding which style of press best fits your needs.

Turret Press – A Single Case Proposition

Most turret presses have a shell plate that holds one empty cartridge at a time. The reloading dies are mounted to a rotatable turret that can be turned to index the die sets over the single cartridge case for each step in the process.

The turret holding the dies is turned to index the correct die over the cartridge for that step in the process.

On most die sets, this requires at least 3 pulls of the handle to finish one loaded cartridge. The steps include:

- The first pull of the handle resizes and de-primes the cartridge case. On most turret presses, a new primer is inserted and seated on the return stroke of the handle.

- After advancing the turret, the second pull of the handle charges the empty primed case with the proper powder load.

- Another turn of the turret and pull of the handle inserts a fresh bullet into the case to the proper depth. On some die sets, this step may also create a crimp around the neck of the case to secure the bullet.

- After this step, the loaded cartridge case is removed and another empty case takes its place. The steps are then repeated.

This is a faster and more efficient process than using a single-stage press to reload a lot of empty brass. Many find this type of press fits their needs very well.

Progressive Reloading Presses – One Pull, One Loaded Bullet

The great thing about a progressive reloading press is the efficiency of the designs. Most progressive presses put the die set on a fixed tool head above the shell plate. The shell plate is designed to rise as the handle is pulled to engage the dies. After each pull of the handle, the shell plate is rotated to re-index the cartridge beneath the next die in the process.

Some progressive reloading presses require manually advancing the shell plate. Others automatically advances cases to the next station at the end of each handle pull and return. A progressive reloader, once all of the cartridge spots on the shell plate are full, drop a reloaded round into the bin with each pull of the handle.

For high volume reloading, a progressive press is much more efficient and generates a higher load rate than other types of presses. If an automatic case feeder and an automatic bullet feeder are installed, these progressive presses can turn out hundreds of loaded rounds per hour.

Finding the Best Progressive Reloading Press For Your Needs

You may be looking for your first reloading press or upgrading your reloading bench. In either case, if you want to invest in a progressive reloading press it pays to do some investigation.

There are several excellent progressive presses on the market from which to choose. Each progressive press features different options that may fit your needs. One important decision is whether to choose an auto progressive reloading press or a manual reloading press.

Best Manual Progressive Reloading Press – Dillon Precision 14261 RL550C Progressive Press

To be honest, I prefer a manual progressive press. In my opinion, a manual progressive press is more reliable and more accurate than many of the auto progressive reloading presses on the market.

My preference is the Dillion RL550C, which is what is installed on my loading bench. This press features many innovations that make it my go-to press for all my reloading needs.

You can purchase a Dillon Precision RL550 and then customize it to your own specifications by adding additional features such as bullet bins, casing bins, a roller handle and low powder and low primer alarms.

These add-ons combined with the standard features of the Dillon Precision press make this my choice for the best manual progressive reloading press.

Features:

Upgraded Design

The RL550C model is an upgrade from the Dillion Precision RL550B model. The frame has been strengthened at key stress points and the upper roller pin on the mechanism is now threaded and includes a lube hole on the end of the pin. A grease gun fitted with a needle-style fitting makes keeping this pin well lubricated for easy reloading.

A Wide Range or Cartridges

Rifle or pistol calibers are no problem from the Dillion Precision RL550C. Caliber conversion kits are available from 32 ACP up to 460 Weatherby. The largest magnum rifle cases are included in the lineup of conversion kits.

Automatic Indexing System

Accurate alignment of your reloader is a critical part of making consistent and accurate cartridges.

The Dillion Precision shell plates automatically align with the tool head mounted on top of the press. Each movement of the shell plate advances to the next step in the reload process and the shell plate is firmly and noticeably locked into place.

Priming System

Primer size is not a problem either. The Dillon Precision RL550c primer system will handle both large and small primers. Primers are easy to load with the primer pickup tubes that can hold 100 primers at a time. The feed system for the primer system is reliable and simple.

Primers are loaded at the end of the first handle pull by pushing gently on the reloader handle to seat the primer safely.

Tool Head Capacity

The Dillion RL550C features quick-change tool heads allowing you to remove and reinstall a set of dies quickly and without the need to reset between caliber changes.

Each tool head will accommodate four dies allowing you to de-prime and resize, load powder, insert a bullet, and crimp the case in one pull of the handle.

The Pros and Cons of the Dillion Precision RL550C Progressive Reloading Press

Pros

- One of the highest production rates of any of the available progressive presses on the market.

- The shell plate design of the RL550C far exceeds those of any other progressive press.

- The number of available add-on options including a shell feeder, powder and primer alarms, among other features can make your reloading press more efficient and effective.

Cons

- This is a manual progressive press and you must advance the shell plate each time you finish a step in the process.

- Dillion equipment is slightly higher priced than other comparable reloading presses.

My Recommendations About the Dillion Precision RL550C Manual Progressive Reloading Press

The best recommendation I can make is the fact that there is a Dillion 550 press mounted on my reloading bench and it gets used several times each week.

My Dillion is an older B model without the upgrades but it has loaded thousands of rounds in different calibers and has never given me a bit of trouble.

Last update on 2022-06-06 at 19:22 / Affiliate links / Images from Amazon Product Advertising API

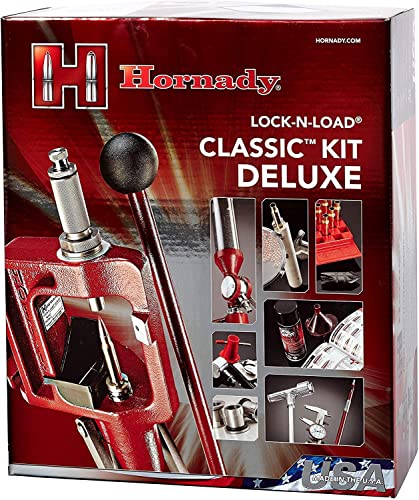

Runner-up Manual Progressive Reloading Press – Hornady Lock-N-Load AP Press

Hornady is another name in the shooting industry that has a solid reputation for quality equipment, parts, and supplies.

In many respects, Hornady is my preferred supplier of reloading supplies such as bullets. It is no wonder that the Hornady Lock-N-Load press makes it on my list as the best progressive reloading press.

Hornady is one of the top brands in the shooting world. For the cost, this may be the best press for the money you can buy.

The Hornady is cheaper than the Dillion Precision press. If an operator desires a budget-priced progressive reloader that doesn’t lack features, this may be the best choice.

Features:

Five Station Tool Head

The Hornady Lock-n-Load reloader has a five-station tool head allowing you to process cartridges that require five stations to complete the reloading process.

This allows you to deprive, resize, prime, powder load, insert a bullet and neck crimp your cartridge quickly and easily.

Patented Lock-n-Load Bushing System

Using Hornady Lock-n-Load bushings, you can do a complete die set change in less than five minutes.

You can install a set of bushings on your existing dies to make them compatible with the Hornady Lock-n-Load tool head. With this system, multiple dies become part of the Hornady system.

Quick Change Metering Inserts

Powder metering is always an issue with automatic powder systems. Hornady addresses this issue with their powder meter that includes quick change inserts. To change from one powder to another, simply switch out the metering insert. For maximum efficiency, put a meter insert with each set of dies.

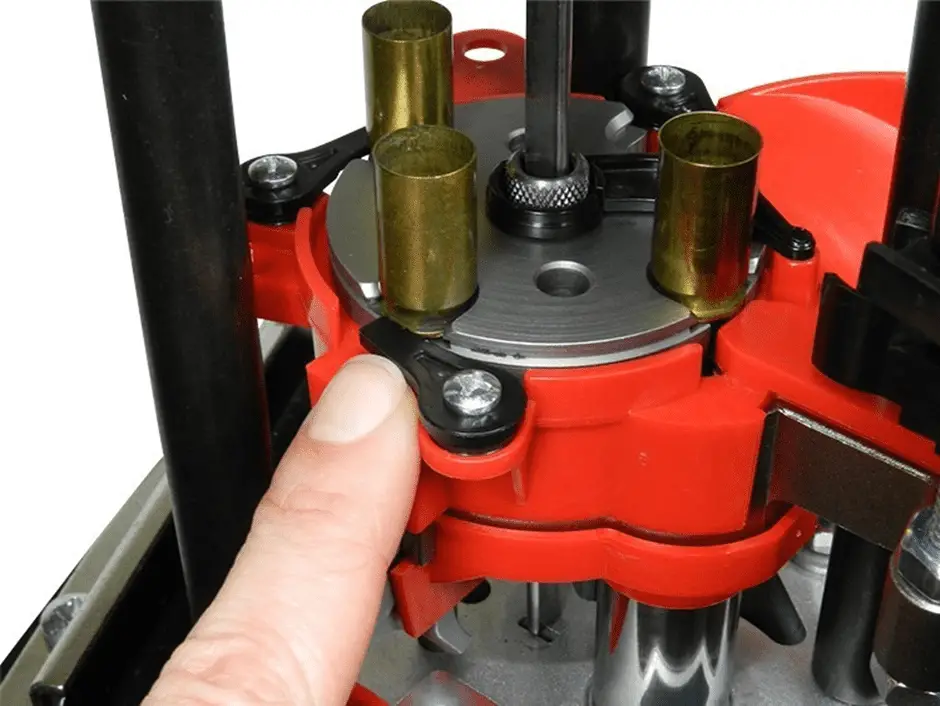

Shell Plate System

The Hornady press uses a universal case retainer spring system that allows inserting or removing a shell case at a point on the rotation. This universal case retainer spring is accompanied by the EZJECT system to ensure 100% reliable ejection of every cartridge time and time again.

Priming System

The Hornady Lock-N-Load system is adaptable for both large and small primers. To change the size of the primer system, three simple steps are the only requirements:

- Change the primer seater punch.

- Change the primer shuttle feed.

- Change the primer feed tube.

This is the whole process to change the primer size. Having both primer sizes allows you to reload almost all pistol and rifle calibers.

Pros and Cons of the Hornady Lock-N-Load Progressive Reloading Press

Pros

- Five Station tool head offers flexibility for your reloading needs.

- The Hornady powder throw is one of the most accurate reloader powder measures on the market.

- You can achieve a very high rate of reloading with the Hornady Lock-N-Load press.

- The easy setup makes this a great press for those who have never used a progressive loader before.

Cons

- While not as expensive as the Dillon system, the entry price is a little steep.

- To achieve the most efficient reloading operation, additional accessories for this press may be required.

My Recommendations on the Hornady Lock-N-Load Progressive Manual Reloading Press

For someone who is just getting into the progressive reloading world, the Hornady Lock-N-Load system is outstanding. This press is easy to set up and operate.

My only concern is the durability of some parts of the system. If you are reloading very large or very long cartridges, the Hornady system may not live up to the task.

Last update on 2022-06-06 at 19:52 / Affiliate links / Images from Amazon Product Advertising API

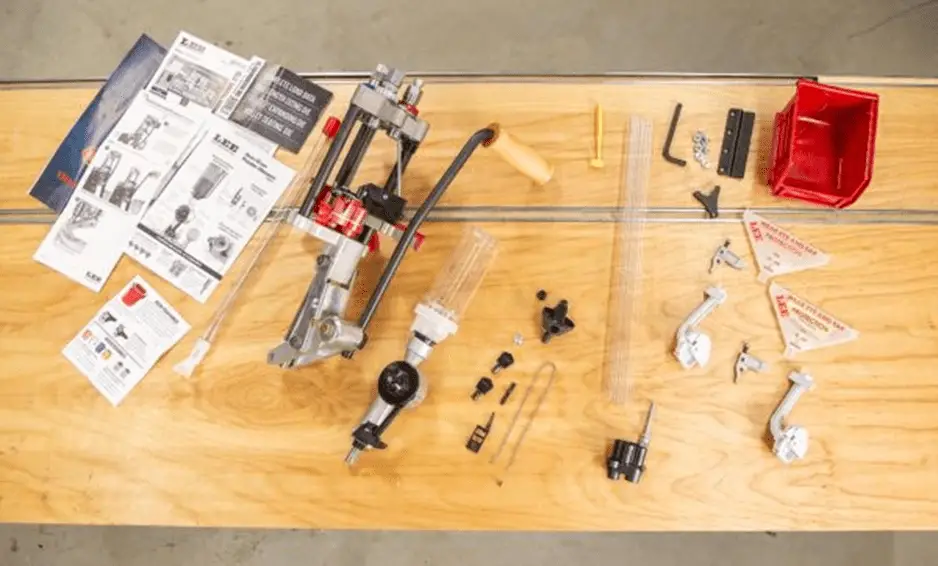

Best Automatic Advancement Progressive Press – Lee Precision, Inc Pro 4000 Progressive Reloading Press

The next step in reducing manual operations in reloading is the Lee Precision, Inc Pro 4000 progressive reloading press.

The Lee system includes an auto case advance system that rotates and indexes the shell plate with each pull of the handle. The auto case feeder that comes with the Lee Pro 4000 reloading press removes one more manual step in the reloading process.

The Lee Precision Pro 4000 is the next evolution in your reloading process. If you need to process a large number of empty cartridges in the least amount of time the Pro 4000 is a great option at a budget price.

This loader is the choice of many small shooting clubs and ranges that can’t justify the price of a commercial reloader for their operation.

Features:

Automatic Cartridge Advance

Automatic advance relieves you of one step in each pull of the reloader handle. You don’t need to remember to turn the shell plate after each process.

As you raise the handle on the Lee 4000 loader, the shell plate turns and then indexes the cartridge at the next reloading station. After 4 pulls of the handle, each subsequent pull of the handle deposits a reloaded cartridge in the catch bin.

Empty Case Feeder

Unlike other reloading presses, the Lee 400 includes a universal case feeder. Most other manufacturers offer the case reloader as an optional accessory. In some cases, the case loaders are caliber specific and involve even more cost. Lee includes a universal case feeder as part of the Pro 4000 kit.

Modular Construction

You aren’t locked into a fully automated process with the Lee Pro 4000 press. The modular construction allows you to use only those features that you need for your reloading project. If you want to use the Lee 4000 as a single-stage press for custom loading, disengage the auto rotation system.

Priming System

Each Lee Pro 4000 reloader uses the Lee Safety Prime system. With this primer system, you can dispense any size or brand of primers with confidence. Primer size changes can be done without making any further adjustments to the press.

Powder Measure

Every Pro 4000 kit includes the Lee Auto Drum Powder Measure that ensures consistent powder drops. You can feed any type of powder through the powder measure and be assured of precise and accurate powder measures.

Pros and Cons of the Lee Precision Pro 4000 Automatic Progressive Reloading Press

Pros

- Simple design and quality construction are hallmarks of the Lee Precision reloading system.

- Reliable and accurate.

- Easy enough for a novice reloader to use with confidence.

- The Lee kits are as complete as you could ask for.

- Budget price compared with other reloaders that don’t automatically advance.

Cons

Larger cartridge cases may not work reliably with the auto-advance system.

My Recommendations on the Lee Precision Pro 4000 Progressive Press

If having an auto-advance press is an important consideration, the Lee Precision Pro 4000 is your best option for a reloading press.

You won’t find another progressive press that includes a case feeder, roller handle, and auto-advance for a price that is usually under $400. Longer cartridges may not work as well with the auto advancement of the shell plate.

LEE PRECISION 223 Remington Pro 4000 Press Kit

- Easy to use with no adjustments; Modular construction allows as much or as little automation as the…

- Cartridge changeover in seconds, including primer size with no adjustments; Breech Lock quick change…

Last update on 2022-06-06 at 19:52 / Affiliate links / Images from Amazon Product Advertising API

Your Needs and Expectations are the Key

If you are ready to leave the world of single-stage press operations and need more volume in less time, a progressive press is probably in your future.

Before you purchase, make sure that the press you choose has the features you need and want. I always advocate keeping things as simple as possible. This holds true for reloading tools as well. The more features and automation means more things to break, get out of adjustment, and need replacement.